Reduce production losses and measurement uncertainty

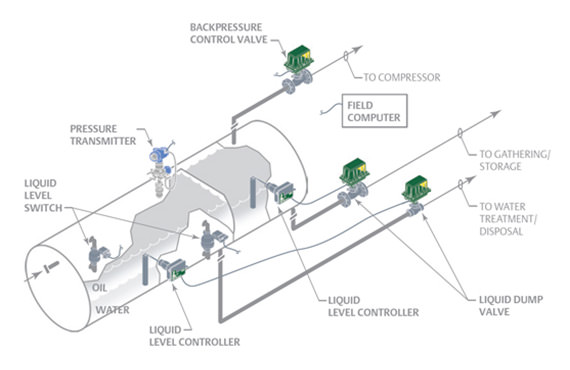

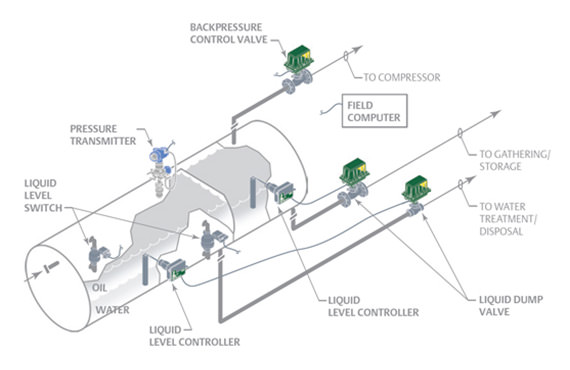

The right instrumentation is critical for effective separator operation.

Level control in a separator controls the interface between the water and the oil (liquid hydrocarbons). There must be sufficient time to create a layer of oil above the free water. The level controller controls the interface level by creating a pad between the water and oil. A weir is used to separate the oil from the water and another controller is used to control the oil level. The natural gas flows on the top of the separator. To maintain the interface level and ensure optimal production out of the separator, the instrumentation is integral to the process.

Trust our team with your level management solutions.

Our team has a wide breadth of solutions for separator level controls. Whether it’s pneumatic or electronic technologies, we have the solution that fits your needs. We work with industry-leading OEMs and contractors to provide level control solutions to the fabricators and contractors with whom you are partnering.