Increase safety with reliable emergency shutdown

Often, wellpads and processing facilities lack dependable external power sources.

This can make your critical safety system, the ESD or emergency shutdown, unreliable. Ever-evolving local government regulations may also influence safety system design to address growing concerns about emissions, contamination and public safety. As a result, operators today need to select the right ESD equipment for their onshore oil and gas operations.

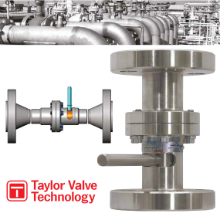

We are the leading provider of pneumatic actuation, ESD valves, and automation solutions in our territory.

Our team of experts provide proven and reliable solutions to help safely shut-down your production or limit the flow of a prolific well. We customize and automate ESD and choke valves using electric, hydraulic or pneumatic actuation packages supplied by Emerson KTM Virgo Series, your own valves, and Emerson Bettis actuators. Customers seeking safe and efficient emergency shutdown capabilities rely on our experts for complete valve and automation solutions.