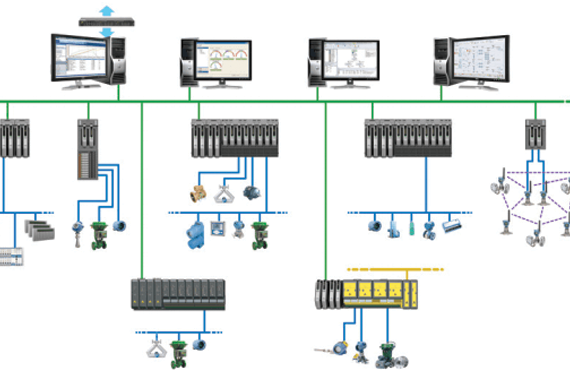

Extending the utility of the control system across the entire manufacturing operation is one of the key value propositions Emerson provides.

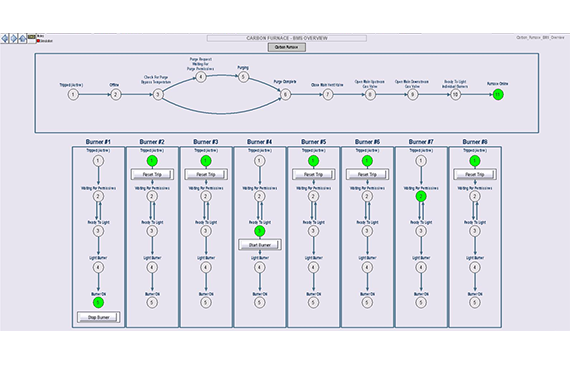

Working with the local Impact Partner brings deep project execution expertise and process control insight to you, to solve unique challenges you may face in start-up, shut-down, and steady state operations.