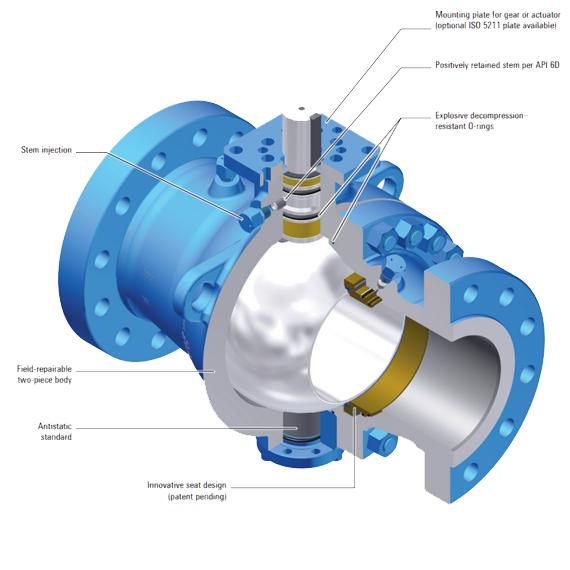

WKM 370D6 ball valves are designed and engineered for heavy-duty performance.

Used in many general-purpose petroleum and chemical process applications, these valves also can be specified for more demanding applications. The WKM 370D6* trunnionmounted ball valve is recognized throughout the world for durability, reliability, and flexibility in many challenging situations.